More information

Food safety requirements

Businesses that produce food products must ensure these products are safe. Consumers should not become ill after consuming their products. The national government inspects whether corporations have drawn up a food safety plan and act in accordance with food preparation regulations. You can read more information from the national government about food safety requirements here.

Food contact and materials

The EFSA is an agency created by the European Union. It offers independent scientific recommendations pertaining to food safety to support the EU’s legislation and policies. Information about food contact materials can also be found on the EFSA’s website. These are materials that come into direct contact with food products, for example packaging materials. The following EFSA articles provide an overview of the regulations pertaining to food contact materials and the rules regarding the use of materials made of (recycled) plastic that come into contact with food:

- Read more about food contact materials.

- Read more about plastics and plastic recycling here.

Approved substances

Materials can only be used for food contact if all substances found in the material have been assessed and approved. In the Netherlands, there are positive lists for substances in plastic, paper and cardboard, coatings, rubber, metal, wood and cork, regenerated cellulose, and textile. Read for more information from the National Institute for Public Health and the Environment (RIVM) about approved substances.

Mineral oils in paper and cardboard packaging materials

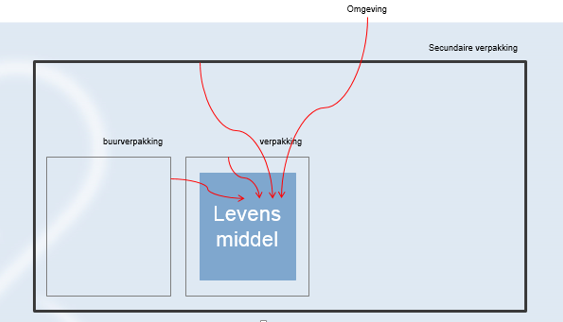

There are several ways in which contaminants found in packaging materials can migrate to food products. One example is the presence of mineral oils in packaging materials made from recycled paper and cardboard. These mineral oils can also end up in food products in other ways, e.g. through the use of lubricating oil and hydraulic oils in harvesting and production machinery.

- In June of 2016, the KIDV released a factsheet on the scope and risks of the presence of mineral oils in packaging materials made from recycled paper and cardboard, including applicable regulations. You can find the “Mineral oils in paper and cardboard packaging materials” factsheet.

- Additionally, the KIDV hosted an information gathering about this topic with several guest speakers from the scientific and corporate communities. You can read the report of the gathering and the speakers’ presentations.

Bisfenol A (BPA)

BPA is used in for example food packaging made from hard plastics and in coatings. The KIDV regularly receives questions from businesses about the use of BPA. It has therefore drawn up a factsheet about the applications of BPA and the applicable regulations. You can find the factsheet “Bisphenol A (BPA) in packaging materials” here.

Ending the use of PVC in packaging materials

In the Framework Agreement for Packaging 2013-2022, the national government, the packaging industry and municipalities have drawn up agreements about reducing the environmental impact through prevention and recycling. One of these agreements concerns ending the use of PVC as a packaging material in supermarkets, unless strictly necessary.

In late 2014, the KIDV drew up a list to clarify what “unless strictly necessary” means. This list goes as follows:

- PVC as a coating in metal packaging materials;

- PVC as a liner for crown caps on so-called “twist-off” bottles for single use;

- PVC as a film to package sprout vegetables, mushrooms, dates, pre-cut vegetables, etc.;

- PVC as a packaging material in the pharmaceutical sector for all legally registered medications, where relevant;

- PVC as a film used to package meat and meat products is not included on the “unless strictly necessary” list, because suitable alternatives – for example Modified Atmosphere Packaging (MAP) –are available.

You can find more information about this list here.