KIDV continues as Verpact

November 6, 2025

What is the best route to a circular chain for multilayer flexible plastic packaging? How can stakeholders achieve this and what are the current barriers? These questions cannot be answered unambiguously. To give the various parties insight into this complex matter, the Netherlands Institute for Sustainable Packaging (KIDV) has produced a so-called Information Map – Towards Circularity of Flexible Plastic Packaging in 2025.

The Information Map was launched on 11 February during the KIDV webinar on flexible plastic packaging. The creation of this map was an initiative of the companies in the KIDV's Community of Practice Flexible Packaging. Participants in this CoP are FrieslandCampina, Intersnack, Jacobs Douwe Egberts, Mars Wrigley, PepsiCo and Unilever. More than two hundred professionals from the international flexible packaging chain attended the webinar 'Unlocking the flexible packaging dilemma' yesterday.

The KIDV is convinced that in order to make flexible plastic packaging circular, changes are needed in its collection, sorting and recycling. The laminated packaging (think of chip bags, packaging for coffee, biscuits and bake-off sandwiches) has a number of major advantages: it has a relatively low environmental impact and it protects its contents so well that little food needs to be wasted. The big disadvantage, however, is that the packaging is not yet recyclable. "Steps have already been taken to make the packaging 'recyclable', but now the whole chain has to get moving", say Niels van Marle and Gijs Langeveld, the KIDV project leaders of the CoP Flexible Packaging.

Van Marle: "Parties in the packaging chain - companies, packaging suppliers, sorting facilities, recyclers, the Dutch Packaging Waste Fund (Afvalfonds Verpakkingen), governments - need guidance if they are to achieve circular flexible packaging in the short term. The KIDV wants to give companies the confidence that investments are worthwhile, even if the results may not be immediately visible." On behalf of the CoP, KIDV asked the Argumentenfabriek to map out this issue, which resulted in the Information Map.

According to the KIDV, the chain partners must jointly make a choice for the route to a circular chain. Van Marle: "They have divergent interests, which sometimes touch each other but often clash as well. We are looking for the best way to align these interests and to guide the parties. The Information Map helps with that. It is a map with clear and concrete information, as a basis for the dialogue between the chain partners to actually get the chain movement going."

Puzzle

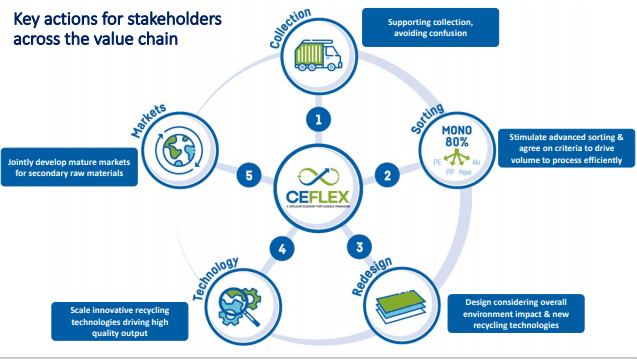

During the online in-depth meeting 'Unlocking the flexible packaging dilemma', various experts and participants of the CoP Laminate Packaging gave their views on the recycling issue. One of them was director Graham Houlder of CEFLEX, a European consortium of more than 180 companies and organizations from the entire flexible packaging chain. Last year, CEFLEX published draft guidelines aimed at the collection, sorting and recycling of laminated packaging and at new end-of-life technologies, among other things. "The circular economy consists of many pieces of the puzzle. The guidelines are the first piece. To put the whole puzzle together and get circularity going, producer responsibility is essential", Houlder said. Click here for his presentation.

Project leader Gijs Langeveld of the CoP Flexible Packaging concluded. "Design guidelines are very important to make packaging recyclable, but this does not yet mean that it will actually be recycled. There are different sorting and recycling routes to build this bridge." With this he was referring to the Roadmap 'Multilayer flexible packaging in a circular economy' published by the CoP last year. The new Information Map is an important tool for implementing this. Click here for the presentation of Gijs Langeveld.

Case studies

PepsiCo and Unilever are participants in the CoP. Dominika Maruszak (PepsiCo) and Thor Tummers (Unilever) presented a case study. Maruszak stated that very little is known about the amount of recyclable films among all packaging waste. In recycling, much attention is paid to PE. A sorting test at the National Test Centre for Circular Plastics showed that PP also makes up a significant proportion of the flow, which can be recycled to a high quality. Tummers zoomed in on the importance of good dialogue between all stakeholders and clear information for consumers, so that they know how to dispose of used packaging. "The industry must then provide a good infrastructure for further sorting and recycling."

Click here for the presentation of Dominika Maruszak. Click here for the presentation of Thor Tummers.

Panel discussion

An important item in the panel discussion, led by Tim Sykes (Packaging Europe), was the state of affairs in chemical recycling, both the possibilities and the 'ifs' and 'buts'. The main conclusion was that, for chemical recycling as well as for mechanical recycling, the sorting must be in order. Tjaco Twigt of the Dutch Packaging Fund: “Sorting is always the key and we should not persist in one system or another. Depending on different factors, different loops are also possible." Other themes in the panel discussion included prevention and the role of government and legislation, both European and national. Other participants in the panel discussion were Arnoud Passenier (Ministry of Infrastructure and Water Management), Jelmer Vierstra (Natuur&Milieu), Dana Mosora (CEFLEX) and Niels van Marle (KIDV).

"We can no longer sit still and wait until everything is perfectly in order," Niels van Marle stated at the end of the meeting. "We need all parties to initiate the transition and look at the big picture. Look for 'no regret' steps, especially when it comes to the use of flexible packaging materials based on polyolefins, such as PE, PP and mixed polyolefins. What can you do to minimize material consumption and adapt your packaging process or use of packaging so that it is at least suitable for recycling? Ask how you can innovate, collaborate and commit to solving our biggest dilemmas."