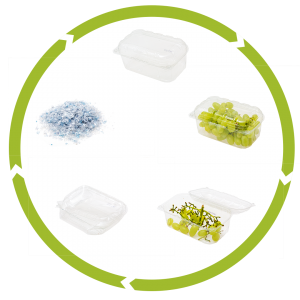

For points 1, 4 and 7: design for recycling

This can be realised through design for recycling and by taking the waste phase into account during the design phase. More information can be found under “Choice of material and packaging process.” Furthermore, you can also use an overview from the KIDV that contains useful tips pertaining to design for recycling.

For points 2 and 3: use more recycled plastic for new packaging materials

By using more recycled plastics in packaging materials, you help increase the demand for recycled plastic and stimulate the increase of the supply. When the market for recycled plastics grows, this will also stimulate businesses to make the separation process for packaging waste more efficient and improve the quality of the output. This, in turn, stimulates innovation in the field.

For points 5 and 6: provide information and clear disposal instructions for consumers

In municipalities that use source separation, consumers play an important role in the separation of packaging waste. If consumers properly separate their packaging waste, source separation can be an effective method. Clearer waste streams are easier to separate for sorters, which provides an excellent starting point for recycling.

In practice, it is not always clear to consumers how they should separate their packaging waste. You can make this easier for them with logical material choices and intuitive designs and by providing clear information and disposal instructions on the packaging itself.