'Packaging without harming people or the environment'

Interview with KIDV director Chris Bruijnes about The State of Sustainable Packaging. In this publication, the KIDV explores how the international packaging chain can use recycling and circularity to ultimately achieve intrinsic sustainability.

“We cannot continue down the path we are on, but we cannot turn away from it either.” This neatly sums up the packaging dilemma that is explored in The State of Sustainable Packaging, published by the Netherlands Institute for Sustainable Packaging (KIDV). In this publication, the KIDV explores how the international packaging chain can use recycling and circularity to ultimately achieve intrinsic sustainability. KIDV director Chris Bruijnes: “Intrinsically sustainable packaging is packaging without harming people or the environment. That is our ultimate goal.”

“We cannot continue down the path we are on, but we cannot turn away from it either.” This neatly sums up the packaging dilemma that is explored in The State of Sustainable Packaging, published by the Netherlands Institute for Sustainable Packaging (KIDV). In this publication, the KIDV explores how the international packaging chain can use recycling and circularity to ultimately achieve intrinsic sustainability. KIDV director Chris Bruijnes: “Intrinsically sustainable packaging is packaging without harming people or the environment. That is our ultimate goal.”

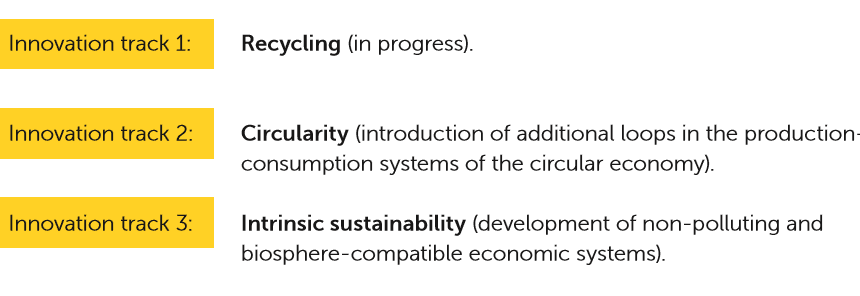

In The State of Sustainable Packaging, the KIDV offers a strategic perspective on the necessary collaboration and innovations with regard to sustainable packaging. “At the moment, all we are doing is chasing our tail and paying the costs of processing,” Bruijnes states. He calls the publication a call to action for the parties in the packaging chain to 'develop a sustainable alternative that critically satisfies our packaging needs and entirely eliminates the negative impact of packaging.' The document analyses thirteen bottlenecks that stand in the way of sustainable packaging. To tackle these bottlenecks, the KIDV has developed a strategy with three innovation tracks that offer short-, medium- and long-term effects.

“Packaging is useful and necessary: it helps prevent damage and food waste. We are working to improve recycling during the waste phase, but there is not enough focus on the reuse of recycled material. Since it is impossible to completely close the material cycle, we should already be working on the next step. With The State of Sustainable Packaging, we are paving the road towards intrinsically sustainable packaging.”

Bottlenecks

“The bottlenecks that inhibit sustainable packaging are diverse,” Bruijnes says. “For a long time, for example, packaging materials were a relatively minor concern or the final piece of the puzzle before putting a product on the market. Demands regarding marketing, sales, shelf-visibility and turnover rate often conflict with sustainability, although we do see some gradual changes. For example, Dutch sector associations have drawn up plans to make their packaging materials more sustainable, which they are now putting into practice. There are more and more 'green’ marketers who opt for sustainable alternatives. In e-commerce, the realisation that there is no need to use additional packaging materials if the product itself already has a decent packaging is dawning as well. However, we also see many businesses replace their plastic packaging materials with alternatives that only appear to be more sustainable, such as plastic-coated cardboard.”

According to Bruijnes, the track of recycling and circularity that our society is currently on will partly solve the packaging dilemma. “There is still plenty of room for improvement, but a fully-closed system is a utopia. A recent study conducted by Wageningen University & Research shows that the maximum recycling rate of plastic packaging materials - if we make optimal use of every step - is circa seventy percent.”

Other issues include the differences in price and quality between recyclates and virgin plastics, the large diversity of plastics and additives and the presence of so-called potentially hazardous interferants in packaging materials and how these behave during and after recycling. Furthermore, the social response against litter and the plastic soup has grown significantly stronger in recent years, which has put businesses under a lot more pressure. Bruijnes: “I should note that the latter is not always justified: consumers sometimes fail to realise that it is better to buy a 400-gram plastic bag of mixed lettuce than buying three separate heads of lettuce, only using half of them and throwing the rest in the trash.”

The fact that it is virtually impossible to make food-grade packaging materials out of recycled materials is also seen as an obstacle. “Although the question remains if it is even desirable to use food-grade packaging materials to make new food-grade packaging materials,” Bruijnes says. In short, he states that there are no easy solutions to the packaging dilemma. “What we need are change and innovation. From more and better recycling, which some countries are already doing, to state-of-the-art innovation methods in our production-consumption systems. We should not be afraid to completely overhaul our production, logistics and consumption.”

Three innovation tracks

The KIDV has developed a three-track innovation strategy to pave to road towards intrinsically sustainable packaging. Track 1 is about more and better recycling and increased efficiency in product-packaging systems. It has a short-term focus and the primary responsibility lies with producers, importers, waste collectors, sorters, recyclers and packaging specialists. Bruijnes: “Think of improving waste collection systems for source separation, the use of subsequent separation, sorting packaging waste into streams of monomaterials and improving the recycling and recyclability of packaging materials.”

Circularity and efficiency in production-consumption systems form the core of innovation track 2, “Circular economy,” which has a short- to medium-term focus. “The complete production-usage system will offer many more possibilities for closing loops than merely the recycling of waste at the end of the packaging chain. The goal is a fully circular economy,” says the KIDV director. He acknowledges that circularity is already part of the strategies that are currently being used in Europe. “The time has come, however, to go the extra mile and ramp up our efforts. Why are we not using one-hundred-percent recycled material for the production of plastic packaging materials for paint or soap?”

Sustainable society

The third innovation track leads towards the intrinsic sustainability of product-packaging combinations. It seeks to answer the question of how we intend to satisfy our needs in the future. “We cannot go down this track with packaging solutions alone; it requires a far more comprehensive approach to our ways of production and consumption. That makes it the most ambitious of the three tracks. Material streams must be both circular and suitable for the biosphere. When it comes to plastics, it is about the combination of recyclability, full usability of the recyclate and ultimately rapid degradability in nature or the ability to turn the used materials into pure raw materials,” Bruijnes says.

At first, it will require the use of ground-breaking innovation methods; only later will it require optimising innovation methods. Bruijnes: “This method of innovation is incompatible with the going concern in business operations; instead, it requires a focus on the future. We advocate the development of new chains with entrepreneurs, researchers, policy makers and citizens/consumers to substantiate and realise the transition towards an intrinsically sustainable society.”

At the moment, it is unclear what social innovations and changes to material streams and technologies track 3 will bring about, although the first concrete examples are already popping up. “The future is hard to predict,” Bruijnes admits, “but our path towards intrinsically sustainable societies is inevitable if we want to stay within the limits of what our planet can take. Way back in the 1970’s, the 'Club of Rome' already predicted this. That is why it is important to go all-in on this innovation track as soon as possible as well.”

The KIDV's work is not done with the publication of The State of Sustainable Packaging. Now it is time to execute the strategy it has devised. There will be an international event on 17 September (16.00-17.30 hrs). Afterwards, various activities with the stakeholders will be organised to inspire them to get to work on the three innovation tracks.

Principles of The State of Sustainable Packaging

|