Incorporating sustainability in packaging

Big bags are not the first thing to come to mind when you think of packaging. In certain sectors, e.g. the food and petrochemical industries, big bags are used on a large scale for the packaging, transportation and storage of large quantities of bulk materials, such as powders and pellets. At LC Packaging, the so-called FIBCs are a symbol of the company's thorough and ambitious sustainability policy.

They can often be seen at construction sites or in the street when people are renovating their garden: enormous plastic bags with loops on them that are filled to the brim with sand, soil or gravel. First and foremost, these bags are sturdy. LC Packaging's big bags offer myriad other properties as well to ensure they properly protect and condition products. This makes them suitable for special applications in industrial environments. It would be a waste to dispose of these bags after only a single use. Marcel Schouten (director of FIBC – Flexible Intermediate Bulk Container) and Lotte Mastwijk (sustainability manager) tell the story of how they worked together with their colleagues and supply chain partners to turn the big bag from a disposable item into a reusable product. This drastically reduces the carbon footprint of the FIBCs, which in turn makes a significant contribution to LC Packaging's ambitious target of realising a fifty-percent emission reduction across the entire value chain by 2030 (compared to the benchmark year of 2021).

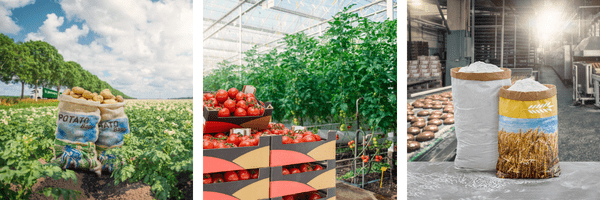

LC Packaging's big bags--of which the company is expected to produce circa twenty million per year by 2030--are a textbook example of how the almost one-hundred-year-old Dutch company is making its packaging more sustainable. At the moment, the big bags represent almost half of the company's total revenue, compared to the various other packaging solutions that it produces. Think of the “handy” plastic bags that contain about twenty-five to fifty kilograms of animal feed. Or the small and large net bags that are used to package ten or twenty-five kilograms of onions or potatoes. Or the cardboard boxes and containers (punnets) used to package fruit or snack vegetables. Last but not least, there are the jute bags which helped the company make a name for itself almost one hundred years ago...

Cocoa beans

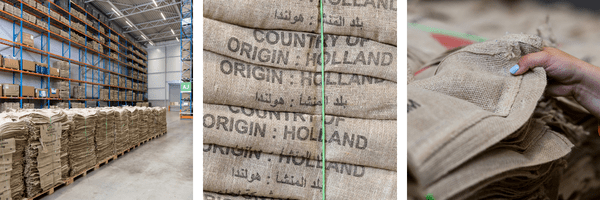

In 1923, Wilhelmus Lammers, the great-grandfather of today's general director Lucas Lammers, started a business dealing in second-hand jute bags in Amsterdam. They arrived in the Netherlands full of cocoa beans from Africa. The bags, of which tens of millions were used every year even then, were cut open at the top to be emptied. Traders like Lammers, and many of his contemporaries, bought the empty bags and cleaned them. They repaired their tops so the bags were ready for reuse in Africa, the Netherlands and other far-off destinations. This was the very definition of reuse. In the 1960s, the company changed its name from NV Zakkenhandel v/h W. Lammers to Lammers & Van Cleeff and--later still--to LC Packaging. The family business grew into a multinational organisation with more than 1,700 throughout Europe, Africa and Asia.

To this day, jute bags are an important product group for LC Packaging. These days, they are mostly used to distribute seed potatoes to destinations around the world. “Jute is a breathable material that retains moisture in a specific way, making this bag the perfect solution for transporting potatoes,” Schouten explains. Nevertheless, the spuds are also being transported in ventilated big bags in volumes of a thousand kilos or more. Lotte Mastwijk: “Jute is an all-natural product made from plant fibres, but its use is starting to present certain challenges. Since it is such a sustainable product, the demand for jute is enormous and the availability of the material is no longer guaranteed. From the car industry to shopping bags: everyone wants to use jute. The plants used for its production mainly grow in India, Bangladesh and China. However, climate change is affecting their cultivation: jute doesn't grow well if it rains too much and the environment is too wet. The unpredictable availability of the material in the future requires us to look ahead.”

Certifications

Two years ago, LC Packaging opened a new head office and distribution centre at a modern industrial park in Waddinxveen. Upon arrival, two things immediately stand out: the parking area, spouting a veritable forest of charging stations for electric cars, and the sticker on the front door, stating that the building has obtained a BREEAM-NL Outstanding certification. This is a certification for sustainable buildings with a minimal environmental impact. Another thing that is impossible to miss is the platinum EcoVadis CSR rating that LC Packaging has received for the second year in a row. EcoVadis is the world's largest provider of sustainability ratings for businesses. LC Packaging obtained this special hallmark with its structured and proactive approach to CSR.

“In our sector, we are seen as a leader in sustainability,” Mastwijk says. She joined LC Packaging in 2015 as a communication officer and saw that the company was implementing various sustainability initiatives. “When we had to conduct an EcoVadis assessment for one of our clients, the resulting score was pretty decent. That inspired us to draw up our first sustainability strategy. We sat down with our clients: what were their sustainable ambitions and what could LC Packaging do to contribute to their goals? Our own employees also came up with themes and targets. We used all this input as the basis for our sustainability strategy for 2017-2022.”

Tailor made advice

“Another important step was the tailor-made advice session with KIDV, during which our key product groups were scrutinised by a team of representatives from every layer of the business. Among other things, we learned that there is quite a difference between a packaging's theoretical recyclability and whether it actually is (or can be) recycled. The material used for our net bags is recyclable, but their structure makes them difficult to process in the recycling system. As a result, these bags are actually deemed non-recyclable by both our own standards and according to KIDV's Recycle Check. We have since raised our standard and will work to improve the recyclability of the bags.”

Looking back on the realisation of LC Packaging's inaugural sustainability strategy, Mastwijk says the company went about the process in a “very comprehensive and very active” manner and that they “learned a whole lot.” In all honesty, she adds: “We came up with as many as fourteen themes with goals for us to focus on, which proved to be far too many for a company of our size. We managed to achieve a number of these goals with flying colours, while others unfortunately proved to be unobtainable. However, we can earnestly say that we now know--after five years of trial and error--what sustainability can do for us and what value we can add to our society. We truly believe that sustainability will one day be just as important and commonplace a factor as quality and price. We presented our new sustainability strategy last spring. Our goals for 2030 are more ambitious and relevant than those of most other parties in our sector.”

Sustainable targets 2030There are three main pillars to LC Packaging's sustainability strategy for 2030: Living WageAll employees of LC Packaging's major production partners must earn a living wage by 2030. In many countries, the legal minimum wage is not enough to maintain a decent standard of living. For one in five employees around the world, a job that pays minimum wage does not provide the necessary means to raise themselves and their families above the poverty line. Most companies ask their suppliers to pay their employees at least a minimum wage. LC Packaging, however, asks for a living wage. 80% of the revenue is generated from packaging coming out of the circular economyPackaging cannot contribute to waste, pollution, climate change or the loss of biodiversity. The remaining twenty percent consists of packaging that, due to legalities, is not (yet) circular. In light of food safety, for example, the use of virgin materials is often required. Likewise, bags used in the chemical sector must be incinerated. 50% emission reduction across the entire value chainTo help avoid the major consequences of climate change, the emission of greenhouse gasses is to be reduced by half by the year 2030, compared to the benchmark year of 2021. This target mainly pertains to the material extraction, production, transport and end-of-life scenarios of LC Packaging's packaging. Ensuring that packaging is reusable, recyclable or compostable will automatically reduce the greenhouse gas emission levels tied to LC Packaging's products. |

“Our mission is not only to be a leader in sustainability, like EcoVadis says. We aspire to be a leader in sustainable packaging,” Mastwijk continues. What is the difference between the two? “We have had many lengthy discussions about how we want to and can integrate sustainability into our business operations. We learned that, although we were quite active and doing quite well with regard to many sustainability themes, our packaging products, of all things, were not particularly sustainable. In order to truly make an impact on people and the environment, we had to make our core business--packaging products--more sustainable. On top of that, this is the only way for us to make sustainability profitable.”

Sweaty palms

Schouten: “It is relatively easy for us to say that ‘we will obtain an EcoVadis medal’ or to sign the Plastic Pact like we did. That does nothing to improve the sustainability of our packaging products, however. We have to incorporate sustainability into our packaging. In doing so, we have charted a difficult course for ourselves. After all, there are no easy and ready-made solutions for us to use. Our ambitions gave location managers in some of the countries we are active in sweaty palms. At first, all they saw were threats and complications. That changes when you take them with you on your journey. Therein lies an important task for management. As the Board of Directors, led by our general director Lucas Lammers, we believe our company's future lies down this road. He says: ‘It is wonderful that we are celebrating our one hundredth anniversary next year, but I want us to be around for another hundred years after that.’ If we keep making the same plastic packaging that we have been producing for so long, there will come a time when they are no longer around or no one wants them anymore.”

“Pursuing our ambitions may temporarily affect our revenue or drive up our costs, because we have to make certain investments. We are active in sixteen countries. Not all of them are reacting to our plans the same way. In some countries, climate change does not exist yet, so to speak. At the same time, other countries are thrilled with our plans. In Germany, for example, the new packaging legislation is clearly focused on sustainability and clients are actively asking about the sustainability of our products. As with any competitive market, there are leaders, followers and those who lag behind. We make sure no one gets left behind: our office in one country may be leader, while another country follows. On top of everything, European legislation is being refined. This will certainly lead to increased awareness in countries where sustainability is not much of an issue at the moment.”

When Marcel Schouten joined LC Packaging in 1995 after completing his studies, big bags were stored in a lonely corner, away from the jute bags and cardboard packaging. Their rise to prominence had begun several years before, with cost reductions being the primary factor. In addition to the simple big bags that are used to transport sand and soil, there are also advanced big bags that meet specific safety standards. Think of e.g. big bags with interwoven carbon fibres to discharge the static electricity that can be generated during loading and unloading. We are also seeing a trend in FIBCs involving barrier liners, which are used, for example, to extend the shelf life of dairy products such as baby formula. These days, millions of FIBCs are used all over the world. There are many manufacturers and the market is fragmented. Schouten: “There are many local players. LC Packaging is one of the only providers to be active in all major European countries. We are also one of the few providers to have our own production sites.” There are two FIBC factories: one in Bangladesh and one in South Africa.” Furthermore, LC sets itself apart with its partnerships with production companies all over the world, because these parties are sustainable as well. “Our clients and production partners highly value our openness and transparency. This open form of collaboration has resulted in partnerships that date back thirty to forty years.”

Plastic PactLC Packaging is a signatory of the Plastic Pact NL and is therefore committed to, among other things, the goal of making all plastic products and packaging reusable by 2025 (where possible and appropriate) and ensuring they are 100% recyclable at the very least. Furthermore, the company strives to reduce its use of plastic by twenty percent, compared to the benchmark year of 2017, by avoiding the unnecessary use of plastic, reusing more plastic and using sustainable alternatives whenever possible. “With our participation in the Plastic Pact NL, we demonstrate our ambition to take on these challenges. At the same time, it serves as an acknowledgement of the fact that the circular economy can only work if we collaborate with other parties in the value chain,” says sustainability manager Lotte Mastwijk. The Plastic Pact NL forms part of the Plastic Pact Network of the Ellen MacArthur Foundation, which consists of national Plastic Pacts in the United Kingdom, France, Chile, the Netherlands, South Africa, Portugal, the US, Poland, Canada, Kenya and India, the European Plastics Pact and that of the region of Australia, New Zealand and islands in the Pacific Ocean. |

Design-for-Recycling

Big bags are made of polypropylene (PP). Sometimes, an inner liner made of polyethylene (PE) is stitched in, making the two hard to separate. “That is an unfortunate combination in terms of recycling. The polyester thread used for the stitches doesn't exactly help, either,” Schouten says. He does believe that the design-for-recycling principle will result in big bags that are made entirely of PP in the foreseeable future. “By then, we will hopefully also have found a way to separate any stitched-in liners into PP and PE after shredding and cleaning the material. These can then be reused as a raw material to make new products. Granulate is in high demand, although it is mostly used for low-grade applications and/or consumer products such as garden furniture, vacuum cleaner casings and suitcases. We would like to use it for the production of new FIBCs. However, it will be quite a challenge to acquire enough recycled material of sufficient quality for all our plastic packaging.”

LC Packaging's efforts to make its big bags more sustainable received a significant impulse last year when a major client approached them. “When a plant manager was tasked with reducing the amount of packaging waste, they also looked at the many big bags with raw materials from their supplier, a material science producer. The bags entered the factory, were emptied and promptly disposed of as waste. Those were our big bags. It is fascinating to see what happens in such cases,” Schouten says. “Normally, we are the requesting party. When we come up with an idea, such as for a reusable solution, our clients are only interested if it is cheaper and does not require too much effort to implement on their part. That is usually the end of the story. In this case, however, one client made a request of another client and that led them back to us. Suddenly, the price of the solution is not that important after all. When a client comes to you with a request, you want to give them what they need.”

Taking sustainability into account

All this has resulted in tests being conducted with a stronger FIBC that can be reused multiple times. The material science producer fills them and delivers them to the manufacturer, who uses the materials in the bags to produce products. LC Packaging’s subsidiary WorldBag, a specialist in the reuse of FIBCs, collects the empty bags from the manufacturer, cleans them and returns them to the material science producer for reuse. “Several years ago, an initiative like this would have been hard to get off the ground, because cost reduction was the name of the game back then. Investing in the proper provision of the empty bags was often not an option. These days, however, sustainability is taken into account as well. After all, our clients have their own emission reduction targets to achieve,” Schouten says.

A recession will hopefully not affect the many circular initiatives being implemented”

“The first time we ran the numbers in 2017, it turned out that the carbon footprint of our big bags is reduced by 43% after reusing them only once and by 66% after reusing them five times. We are currently redoing our calculations and taking a close look at every component because we want to be absolutely certain that we have our facts straight. Now that everything is getting more expensive, after COVID-19 and since the start of the war in Ukraine, we see that buyers are once again being told to mind the costs. I hope a recession will not affect the many circular initiatives being implemented.”

LC Packaging is staying its course no matter what and will scale up its reuse option together with WorldBag. “Close to our head office, we now have a small cleaning unit where we can dry clean big bags. This allows us to quickly scale up our capacity from several tens of thousands to several hundred thousand bags. The next step will be to set up additional cleaning sites across Europe to avoid having to drive trucks from, for example, the south of Spain to the Netherlands full of big bags .” LC Packaging is also testing the possibility of wet cleaning its big bags with large industrial washing machines. “We see the potential of both techniques. By utilising a combination of dry and wet cleaning methods, we believe more FIBCs can be made suitable for reuse.”

In addition to the aforementioned design-for-recycling method, recyclate is used to further improve the sustainability of the bags. Schouten: “We are currently able to produce big bags with 30% rPP without increasing the weight of the material and while retaining the same durability and safety as a bag made from virgin material. We can use either post-industrial or post-consumer recyclate to attain that target of thirty percent. In the current market, there is a limit to the amount of available rPP. At the moment, not all production lines are able to produce rPP. Investments in the future expansion of our production capacity and finding new ways of obtaining rPP material are key concerns for us right now.”

Plastic BankThe onions of M.B. Nieuwenhuijse BV are sent all over the world in LC Packaging's plastic net bags. Their net structure makes the bags difficult to recycle, especially in countries with an underdeveloped infrastructure for waste collection, sorting and recycling. Following a tip from KIDV, the onion producer and the packaging manufacturer signed an agreement with Plastic Bank. This organisation prevents plastic from ending up in the ocean by offering rewards to plastic collectors in vulnerable regions. People can use this reward to pay for essentials such as food, cooking fuel, tuition and health insurance. The collected plastic is processed in order to be reintegrated into the global supply chain. Every year, this initiative keeps 50,000 kg of plastic out of the world's oceans. |