Select the right Recycle Check

This manual is intended to support you in choosing the right Recycle Check. In the background documents, several packaging examples have been further elaborated per step. If after reading this manual you are still unsure about which Recycle Check to select, please contact us via the KIDV Helpdesk.

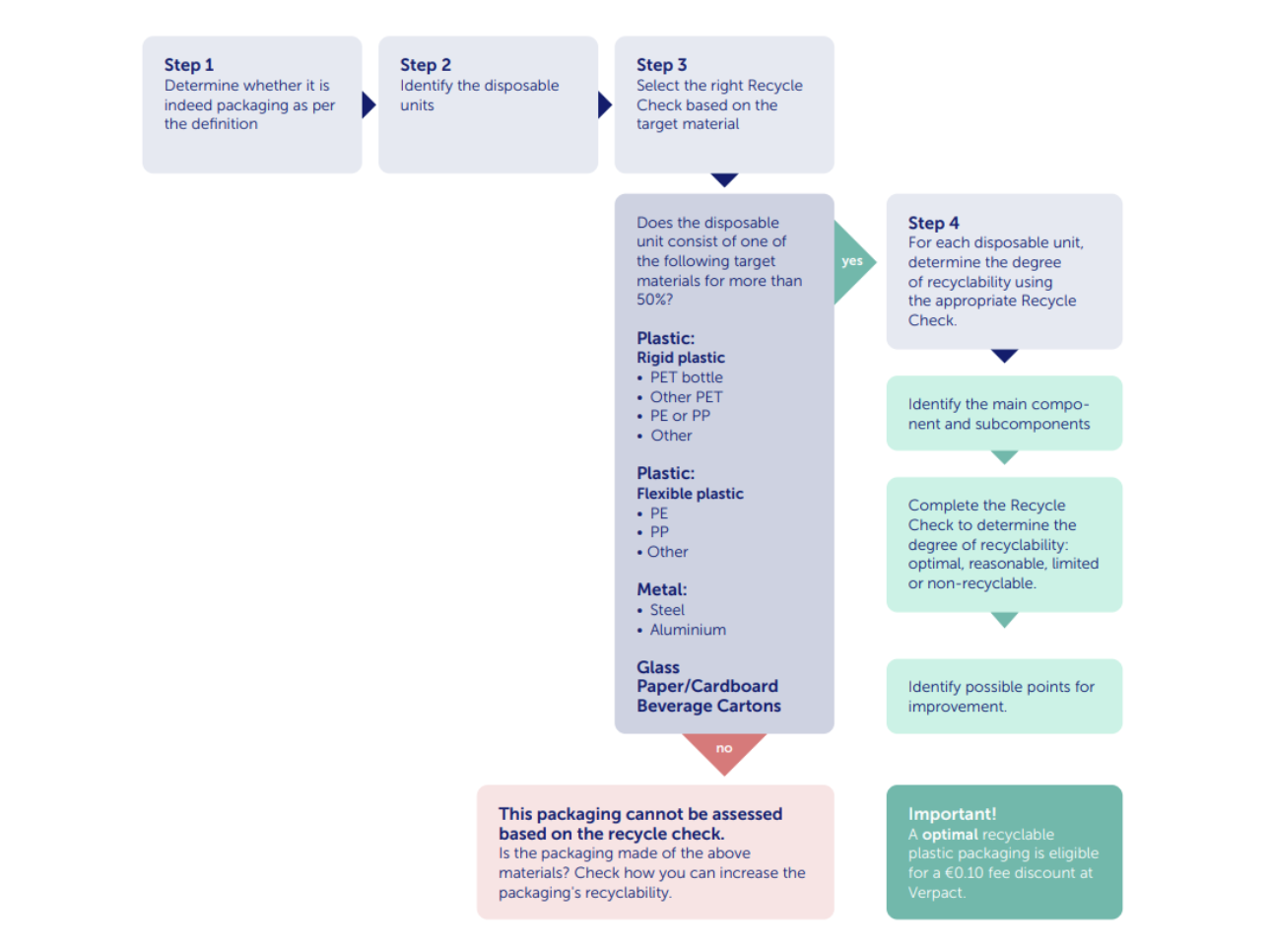

A preview of these steps is provided in the figure below:

The KIDV Recycle Checks were developed specifically to assess the recyclability of packaging (step 1). Packaging often consists of several different components, which may or may not be made of different materials, which users discard at different times. This affects the packaging's overall recyclability. The KIDV Recycle Checks first splits packaging up into its constituent disposable units (steps 2 and 3) and then into a main component and subcomponents (step 4). To determine which Recycle Check(s) should be completed, it is important to first determine which disposable units the packaging consists of, and then to categorise these units by material. This page explains these terms and details the steps for choosing the right Recycle Check.

-

Step 1. Determine whether it is indeed packaging

KIDV Recycle Checks can only return a reliable outcome for packaging. Therefore, it must first be verified that the object to be assessed meets the definition of packaging. The KIDV uses the following definition for that:

Packaging: "All products, made of materials of any kind, that can be used to contain, protect, ship, deliver and offer other products, ranging from raw materials to finished products, along the entire pathway from producer to user or consumer, including disposable items used for this purpose."

For the full definition of 'packaging', see Verpact's policy document. If in doubt about whether something does indeed constitute packaging, consult the (non-exhaustive) Packaging Catalogueon Verpact's website.

-

Step 2. Identify the disposable unit(s)

Most packaging is discarded in its entirety after use and is, therefore, considered a single disposable unit. Packaging that is not discarded in its entirety but as several separate components consists of multiple disposable units.

Whether different components or materials go through the sorting and recycling process together or separately can have a significant impact on recyclability. In practice, a single piece of packaging can consist of highly recyclable, moderately recycle and poorly recyclable disposable units at the same time.

The KIDV goes by the principle that each packaging consists of a single disposable unit, unless:

· it consists of several unconnected components.

· part of the packaging must be permanently and completely removed in order to use the product.

· it features components, such as a lid, that can be detached by applying slight mechanical force

Component detachment

Manufacturers are required to show that a particular component will detach when slight mechanical force is applied and cannot rely simply on samples prepared in a lab. The test should be reproducible with units of packaging filled in at least three different production runs.

Simple detachment test - release liner

You can test whether a release liner detaches when slight mechanical force is applied by grabbing the open, empty packaging by the release liner and shaking it. If the foil comes off easily, it is deemed an individual disposable unit. At the start of the test, at least 25% of the release liner must still be attached to the rest of the packaging.

Simple detachment test - lid

You can test whether a lid detaches when slight mechanical force is applied by squeezing the empty packaging with the lid on. If the lid pops off completely, it is deemed an individual disposable unit.

Detachment test - sleeve

Some units of packaging feature a sleeve that is supposed to come off entirely when the packaging is compressed. This includes plastic cups with a perforated cardboard sleeve that is designed to detach when the cup is compressed. There is a protocol to test whether cup and sleeve indeed detach from each other and behave like individual disposable units. Called the Pollution and Compression Protocol, this protocol is available on the protocols page of the KIDV website.

Cardboard sleeve

If plastic packaging comes with a cardboard sleeve around it that consumers do not undo, but which has been shown to come loose during collection and sorting, the sleeve and packaging behave as individual disposable units. It must then be taken into account that in this case the cardboard sleeve will end up in the wrong sorting stream and must be considered non-recyclable.

-

Step 3. Categorise the disposable unit(s)

The Recycle Check involves completing an individual checklist for each disposable unit. For each unit, determine the most common overarching and, if applicable, specific material type (see list below) to categorise the unit. The type of material that makes up at least 50% of the unit's weight determines what category the unit falls into. This is also referred to as the target material. If none of the types of material make up more than 50%, the disposable unit cannot be assessed using a Recycle Check. The packaging should then be adapted.

The types of material:

- Rigid plastic

- PET bottle

- Other PET (incl. PET trays)

- PE/PP

- Other rigid plastic

- Flexible plastic

- PE

- PP

- Other flexible plastic

- Metal

- Steel

- Aluminium

- Glass

- Paper / cardboard

- Beverage cartons

After choosing the appropriate Recycle Check to assess the recyclability of the disposable unit, the next step is to identify the main component and any subcomponents.

The main component of packaging is that which holds the product, and usually the component that makes up most of the packaging's weight. Besides its main component, a disposable unit often also has one or more subcomponents. These are added components, such as labels and closures, which are processed along with the main component in the recycling process.